Stàilinn Cheàrn ASTM Carbon Stàilinn Co-ionann Ceàrn Iarainn Cruth Iarainn Bàr Ceàrn Stàilinn Tlàth

Mion-fhiosrachadh Toraidh

Bàr ceàrnach 2x2, ris an canar cuideachd iarann ceàrnach no bàr-L, 's e bàr meatailt a chaidh a chruthachadh aig ceàrn cheart. Tha dà chas de dh'fhaid cho-ionann no neo-ionann ann agus tha e air a chleachdadh ann an grunn thagraidhean structarail is ailtireil. Mar as trice bidh bàraichean ceàrnach air an dèanamh de stàilinn, stàilinn gun smal, no alùmanum.

Dh’fhaodadh mion-fhiosrachadh sònraichte bàr ceàrnach atharrachadh a rèir an stuth, na tomhasan agus an cleachdadh a tha san amharc. Airson fiosrachadh mionaideach mu bhàr ceàrnach sònraichte, is dòcha gum feum thu sùil a thoirt air mion-chomharrachadh an neach-dèanamh no bruidhinn ri innleadair structarail.

Ma tha ceist shònraichte agad mu bhàraichean ceàrnach, na bi leisg faighneachd agus nì mi mo dhìcheall am fiosrachadh a dh’ fheumas tu a thoirt dhut.

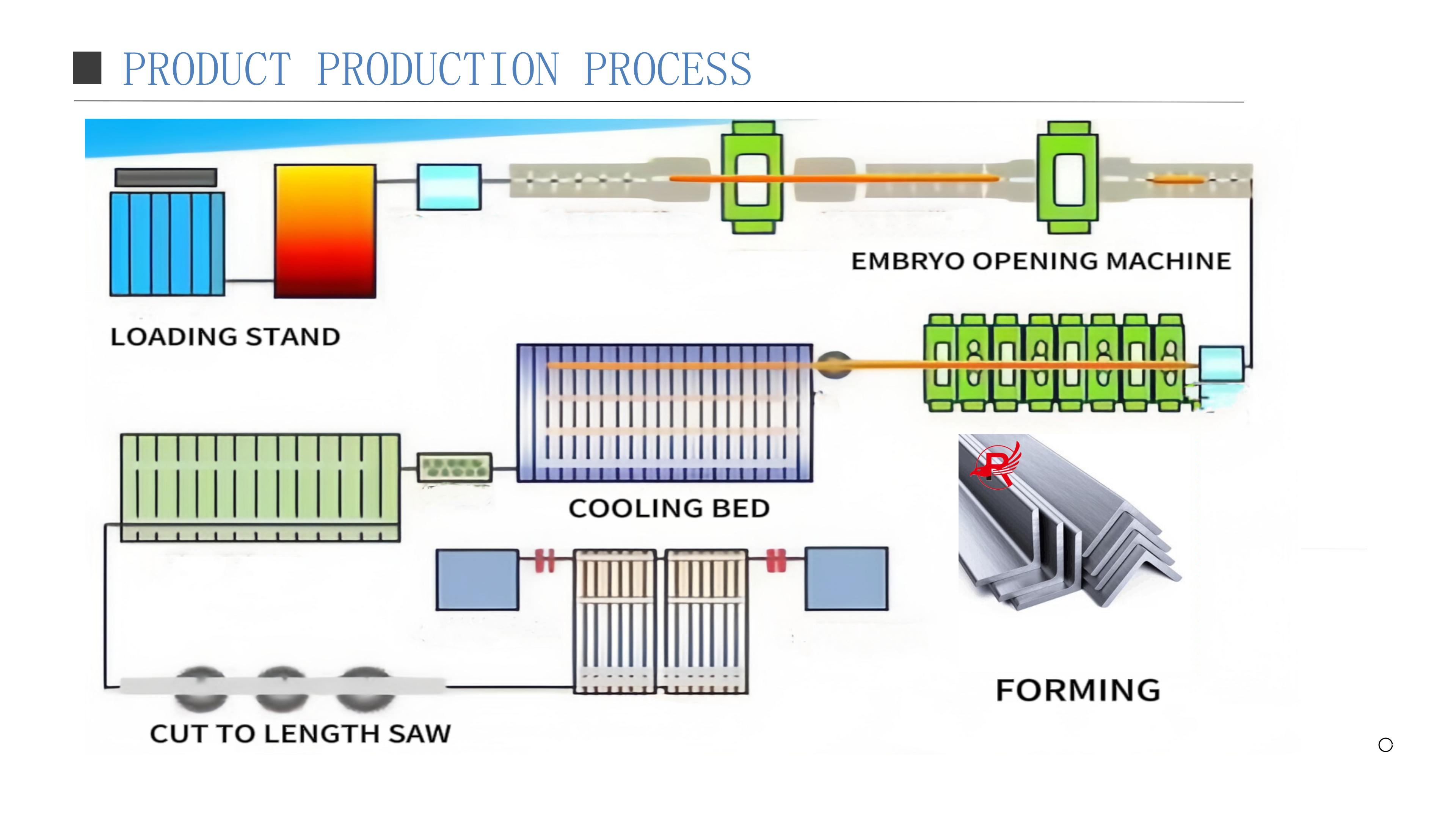

Bàr ceàrnach 40x40x4'S e toradh stàilinn a th' ann an carbon a chaidh a chruthachadh le bhith a' roiligeadh leac stàilinn charboin gu teth a-steach don chumadh ceàrnach a tha thu ag iarraidh. Tha am pròiseas seo a' toirt a-steach teasachadh na stàilinn gu teòthachd àrd agus ga chur tro shreath de rolairean gus an cumadh agus na tomhasan deireannach fhaighinn. Tha am bàr ceàrnach a thig às a sin air a chomharrachadh leis a chumadh ceart-cheàrnach, le taobhan co-ionnan agus oisean ceart-cheàrnach.

Bithear a’ cleachdadh bàraichean ceàrn iarainn charboin teth-roilichte gu cumanta ann an togail, innleadaireachd structarail, tagraidhean gnìomhachais, agus saothrachadh air sgàth an neart, an iomadachd, agus an èifeachdas cosgais. Faodar an cleachdadh ann an grunn thagraidhean structarail is taice, a’ gabhail a-steach togail frèamaichean, neartachadh, taicean, agus neartachadh airson togalaichean, drochaidean, innealan, agus uidheamachd.

Mar as trice, bidh na bàraichean ceàrnach seo air an dèanamh à stàilinn charboin, a tha ainmeil airson a neart tensile àrd agus a sheasmhachd. A bharrachd air an sin, faodar an giullachd tuilleadh tro ghearradh, drileadh, tàthadh, agus dòighean saothrachaidh eile gus freagairt air riatanasan pròiseict sònraichte.

| Ainm Bathar | Ceàrn Stàilinn, Stàilinn Ceàrn, Ceàrn Iarainn, Bàr Ceàrn, Ceàrn MS, Ceàrn Stàilinn Charboin |

| Stuth | Stàilinn charboin/stàilinn bhog/stàilinn neo-aloidh agus aloidh |

| Ìre | SS400 A36 ST37-2 ST52 S235JR S275JR S355JR Q235B Q345B |

| Meud (Co-ionann) | 20x20mm-250x250mm |

| Meud (neo-ionann) | 40 * 30mm-200 * 100mm |

| Fad | 6000mm/9000mm/12000mm |

| Coitcheann | GB, ASTM, JIS, DIN, BS, NF, msaa. |

| Fulangas tighead | 5%-8% |

| Iarrtas | Meacanaigeach is saothrachadh, structar stàilinn, togail shoithichean, drochaidean, clasaichean chàraichean, togail, sgeadachadh. |

| Stàilinn ceàrn co-ionnan | |||||||

| Meud | Cuideam | Meud | Cuideam | Meud | Cuideam | Meud | Cuideam |

| (MM) | (kg/m) | (MM) | (kg/m) | (MM) | (kg/m) | (MM) | (kg/m) |

| 20*3 | 0.889 | 56*3 | 2.648 | 80*7 | 8.525 | 12 * 10 | 19.133 |

| 20*4 | 1.145 | 56*4 | 3.489 | 80*8 | 9.658 | 125 * 12 | 22,696 |

| 25*3 | 1.124 | 56*5 | 4.337 | 80 * 10 | 11.874 | 12*14 | 26.193 |

| 25*4 | 1.459 | 56*6 | 5.168 | 90*6 | 8.35 | 140 * 10 | 21.488 |

| 30*3 | 1.373 | 63*4 | 3.907 | 90*7 | 9.656 | 140 * 12 | 25.522 |

| 30*4 | 1.786 | 63*5 | 4.822 | 90*8 | 10.946 | 140 * 14 | 29.49 |

| 36*3 | 1.656 | 63*6 | 5.721 | 90 * 10 | 13.476 | 140 * 16 | 33.393 |

| 36*4 | 2.163 | 63*8 | 7.469 | 90 * 12 | 15.94 | 160 * 10 | 24.729 |

| 36*5 | 2.654 | 63 * 10 | 9.151 | 100*6 | 9.366 | 160 * 12 | 29.391 |

| 40 * 2.5 | 2.306 | 70*4 | 4.372 | 100*7 | 10.83 | 160 * 14 | 33.987 |

| 40*3 | 1.852 | 70*5 | 5.697 | 100*8 | 12.276 | 160 * 16 | 38.518 |

| 40*4 | 2.422 | 70*6 | 6.406 | 100 * 10 | 15.12 | 180 * 12 | 33.159 |

| 40*5 | 2.976 | 70*7 | 7.398 | 100 * 12 | 17,898 | 180 * 14 | 38.383 |

| 45*3 | 2.088 | 70*8 | 8.373 | 100*14 | 20.611 | 180 * 16 | 43.542 |

| 45*4 | 2.736 | 75*5 | 5.818 | 100*16 | 23.257 | 180 * 18 | 48.634 |

| 45*5 | 3.369 | 75*6 | 6.905 | 110*7 | 11.928 | 200*14 | 42,894 |

| 45*6 | 3.985 | 75*7 | 7.976 | 110*8 | 13.532 | 200*16 | 48.68 |

| 50*3 | 2.332 | 75*8 | 9.03 | 110 * 10 | 16.69 | 200 * 18 | 54.401 |

| 50*4 | 3.059 | 75 * 10 | 11.089 | 110 * 12 | 19.782 | 200 * 20 | 60.056 |

| 50*5 | 3.77 | 80*5 | 6.211 | 110 * 14 | 22.809 | 200 * 24 | 71.168 |

| 50*6 | 4.456 | 80*6 | 7.376 | 125*8 | 15.504 | ||

Feartan

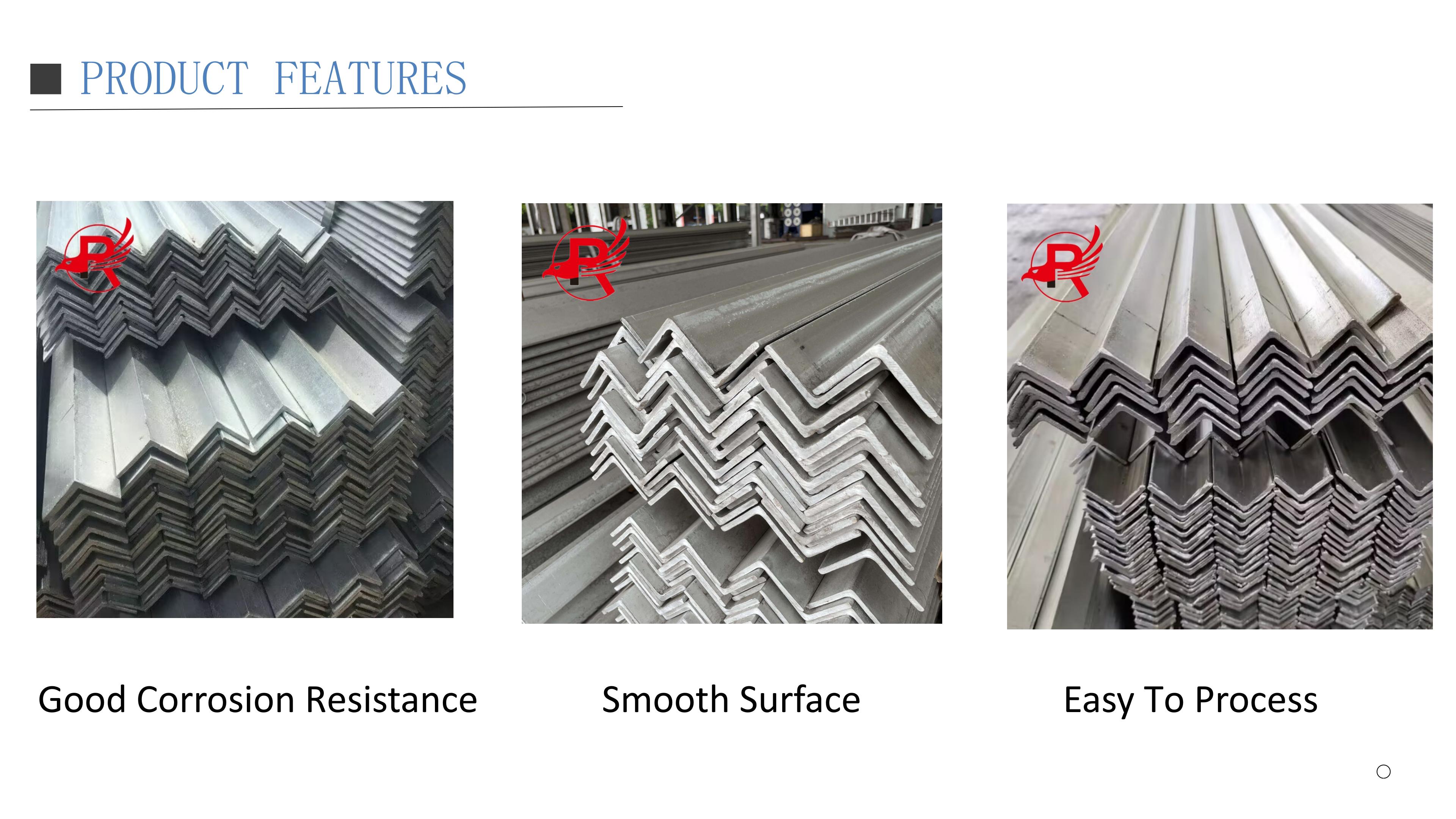

Bàr ceàrnach 50x50x6mm, ris an canar cuideachd ceàrnan iarainn ceàrnach no stàilinn, tha iad nan bàraichean meatailt cumadh L a thathas a’ cleachdadh gu cumanta ann an togail, saothrachadh, agus diofar thagraidhean structarail. Seo cuid de na feartan agus na cleachdaidhean cumanta a th’ aig bàraichean ceàrnach:

Feartan:

- Taic Structarail: Bithear a’ cleachdadh bàraichean ceàrnach gu cumanta gus taic structarail a thoirt seachad ann an togail thogalaichean. Bithear gan cleachdadh gu tric gus oiseanan a fhrèamadh, taic a thoirt do bhìmean, agus joints a neartachadh.

- Iomadachd: Faodar bàraichean ceàrnach a ghearradh, a dhrileadh, a thàthadh agus a làimhseachadh gu furasta gus freagairt air riatanasan structarail sònraichte, gan dèanamh ioma-chruthach airson raon farsaing de thagraidhean.

- Neart agus Seasmhachd: Tha dealbhadh L-chruthach nam bàraichean ceàrnach a’ toirt neart agus cruas nàdarrach dhaibh, gan dèanamh freagarrach airson tagraidhean giùlain luchdan agus teannachaidh.

- Meudan is Tiughan Diofar: Tha bàraichean ceàrnach rim faighinn ann an grunn mheudan, thiughan is fhaid gus freagairt air diofar fheumalachdan structarail is gnìomhachais.

Cleachdaidhean Cumanta:

- Togail: Tha bàraichean ceàrnach air an cleachdadh gu farsaing ann an gnìomhachas an togail airson frèamaichean, structaran taice, agus bracing ann an togalaichean, drochaidean, agus pròiseactan bun-structair eile.

- Saothrachadh: Bithear gan cleachdadh ann an saothrachadh innealan, uidheamachd agus àrd-ùrlaran gnìomhachais air sgàth an neart agus an cruas.

- Sgeilpichean is Racaichean: Bithear a’ cleachdadh bàraichean ceàrnach gu cumanta gus aonadan sgeilpichean, racaichean stòraidh, agus structaran taigh-bathair a thogail air sgàth an comasan giùlain luchdan.

- Plàtaichean Càraidh: Faodar an cleachdadh mar phlàtaichean càraidh gus joints agus ceanglaichean fiodha a neartachadh ann an tagraidhean obair-fiodha agus saorsainneachd.

- Cleachdaidhean Sgeadachaidh: A bharrachd air cleachdaidhean structarail is gnìomhachais, faodar bàraichean ceàrnach a chleachdadh cuideachd airson adhbharan sgeadachaidh, leithid ann an dèanamh àirneis agus dealbhadh ailtireil.

Iarrtas

bàr ceàrn carbaintha iomadh cleachdadh aca thar diofar ghnìomhachasan air sgàth an neart, an seasmhachd agus an iomadachd. Seo cuid de na cleachdaidhean cumanta:

TogailTha bàraichean ceàrnach air an cleachdadh gu farsaing ann am pròiseactan togail airson frèamaichean, structaran taice, agus neartachadh. Tha iad air an cleachdadh ann am frèamaichean thogalaichean, trusganan mullaich, neartachaidhean balla, agus co-phàirtean structarail eile.

SaothrachadhTha na bàraichean ceàrnach seo air an cleachdadh san roinn saothrachaidh airson frèamaichean uidheamachd, bunaitean innealan, sgeilpichean, agus diofar structaran taice a chruthachadh taobh a-staigh goireasan gnìomhachais.

Bun-structarAnns na roinnean bun-structair agus innleadaireachd, thathas a’ cleachdadh bàraichean ceàrnach ann an togail dhrochaidean, slighean coiseachd, rèilichean, agus pròiseactan eile co-cheangailte ri bun-structar.

Chàraichean agus còmhdhailBithear a’ cleachdadh bàraichean ceàrnach ann an dèanamh frèamaichean charbadan, chassis, agus co-phàirtean structarail eile ann an gnìomhachasan nan càraichean agus còmhdhail.

Innealan agus uidheamTha iad air an cleachdadh ann an togail frèamaichean innealan is uidheamachd, a bharrachd air airson camagan taice is braces a chruthachadh.

Structaran mara agus far a’ chladaichAnn an tagraidhean mara agus far-oirthir, thathas a’ cleachdadh bàraichean ceàrnach airson taicean structarail, togail shoithichean agus togail àrd-ùrlaran far-oirthir.

Gnìomhachas lùthaAnns an roinn lùtha, thathas a’ cleachdadh bàraichean ceàrnach airson structaran taice a thogail airson àrd-ùrlaran ola is gas, a bharrachd air ann an togail loidhnichean-phìoban agus bun-structair co-cheangailte riutha.

Cleachdaidhean ailtireachdFaodar bàraichean ceàrnach a thoirt a-steach do dhealbhaidhean ailtireil airson adhbharan sgeadachaidh agus structarail, leithid ann am balustrades, staidhrichean, agus obair-mheatailt sgeadachail.

Tha na tagraidhean seo a’ sealltainn cho feumail ‘s a tha bàraichean ceàrnach iarainn charboin teth-roilichte ann a bhith a’ toirt seachad taic structarail agus seasmhachd thar diofar ghnìomhachasan agus phròiseactan togail.

Pacadh & Luingearachd

Stàilinn ceàrnachmar as trice bidh e air a phacaigeadh gu h-iomchaidh a rèir a mheud agus a chuideam rè còmhdhail. Am measg nan dòighean pacaidh cumanta tha:

Pasgadh: Mar as trice bidh stàilinn ceàrnach nas lugha air a pasgadh le teip stàilinn no plastaig gus dèanamh cinnteach à sàbhailteachd agus seasmhachd an toraidh rè còmhdhail.

Pacadh stàilinn ceàrnach ghalbhanaichte: Ma tha e na stàilinn ceàrnach ghalbhanaichte, mar as trice bithear a’ cleachdadh stuthan pacaidh dìon-uisge agus taiseachd, leithid film plastaig dìon-uisge no carton dìon-taiseachd, gus casg a chuir air oxidation agus creimeadh.

Pacadh fiodha: Faodar stàilinn ceàrnach de mheud no cuideam nas motha a phacaigeadh ann am fiodh, leithid paileatan fiodha no cùisean fiodha, gus taic agus dìon nas fheàrr a thoirt seachad.

TADHAL LUCHD-ceannach

Ceistean Cumanta

1. Ciamar as urrainn dhomh luachan fhaighinn bhuat?

Faodaidh tu teachdaireachd fhàgail thugainn, agus freagraidh sinn a h-uile teachdaireachd ann an àm.

2. An lìbhrig thu am bathar ann an àm?

Tha, tha sinn a’ gealltainn gun toir sinn seachad toraidhean den chàileachd as fheàrr agus gun lìbhrigear iad ann an deagh àm. Is e onair prionnsapal na companaidh againn.

3. An urrainn dhomh sampallan fhaighinn mus cuir mi òrdugh a-steach?

'S e, gu dearbh. Mar as trice bidh na sampallan againn an-asgaidh, is urrainn dhuinn a dhèanamh leis na sampallan no na dealbhan teicnigeach agad.

4. Dè na teirmichean pàighidh agad?

Is e an teirm pàighidh àbhaisteach againn tasgadh 30%, agus an còrr an aghaidh B / L. EXW, FOB, CFR, CIF.

5. A bheil thu a’ gabhail ris an sgrùdadh treas-phàrtaidh?

'S e, gu tur, tha sinn a' gabhail ris.

6. Ciamar a tha sinn a’ cur earbsa anns a’ chompanaidh agaibh?

Tha sinn air a bhith gu sònraichte a’ dèanamh gnìomhachas stàilinn airson bhliadhnaichean mar sholaraiche òir, le prìomh oifis ann an sgìre Tianjin, fàilte gus sgrùdadh a dhèanamh ann an dòigh sam bith, gun teagamh.